Surface roughness

Development

Inordertostudytheinfluenceofsurfaceroughnessontheperformanceofpartsandtheneedtomeasuresurfacemicroscopicunevenness,fromthelate1920stothe1930s,GermanySomeexpertsintheUnitedStates,theUnitedKingdomandothercountrieshavedesignedandmanufacturedprofilerecordersandprofilemeters.Atthesametime,theyhavealsoproducedinstrumentssuchaslightsectionmicroscopesandinterferencemicroscopesthatuseopticalmethodstomeasuresurfacemicroscopicunevenness,whicharequantitativelyevaluated.Thesurfaceroughnesscreatestheconditions.Sincethe1930s,quantitativeevaluationparametersforsurfaceroughnesshavebeenstudied.Forexample,AbbottintheUnitedStatesproposedtousethedepthfromthetopofthesurfaceprofileandthesupportlengthratecurvetocharacterizethesurfaceroughness.In1936,Schmaltzpublishedamonographonsurfaceroughness,andmaderecommendationsforthestandardizationofevaluationparametersandvaluesofsurfaceroughness.

However,theuseofroughnessevaluationparametersandtheirvalueshastrulybecomeawidelyacceptedstandardsincethereleaseofthecorrespondingnationalstandardsinvariouscountriesinthe1940s.First,theUnitedStatesissuedtheASAB46.1nationalstandardin1940.Afterseveralrevisions,itbecamethecurrentstandardANSI/ASMEB46.1-1988"Surfacestructuresurfaceroughness,surfacewavinessandprocessingtexture",thestandardThemidlinesystemwasadopted,andRawasusedasthemainparameter;thentheformerSovietUnionissuedtheGOCT2789-1945"SurfaceFinish,SurfaceMicrogeometry,GradingandRepresentation"nationalstandardin1945,whichwasrevisedthreetimestobecomeGOCT2789-1973.Surfaceroughnessparametersandcharacteristics",thestandardalsoadoptsthecenterlinesystem,andstipulates6evaluationparametersincludingtherootmeansquaredeviationoftheprofile(nowRq)andtheircorrespondingparametervalues.Inaddition,thestandardsofotherindustriallydevelopedcountriesweremostlyformulatedinthe1950s.Forexample,theFederalRepublicofGermanyissuedDIN4760andDIN4762standardsonsurfaceroughnessevaluationparametersandterminologyinFebruary1952.

Evaluationparameters

Heightcharacteristicparameters

ArithmeticmeandeviationofcontourRa:inthesamplinglength(lr)Thearithmeticmeanoftheabsolutevalueoftheinternalcontourdeviation.Inactualmeasurement,themorethenumberofmeasurementpoints,themoreaccurateRais.

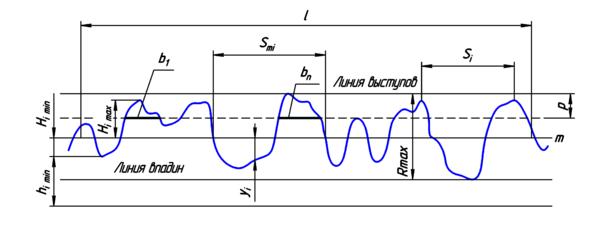

MaximumcontourheightRz:thedistancebetweenthetoplineofthecontourandthebottomlineofthevalley.

Raispreferredinthecommonlyusedrangeofamplitudeparameters.Before2006,therewasalsoanevaluationparameterinthenationalstandard,whichwas"theten-pointheightofmicro-roughness"representedbyRz,andthemaximumheightofthecontourwasrepresentedbyRy.After2006,thenationalstandardcanceledtheten-pointheightofmicro-roughnessandadoptedRz.Indicatesthemaximumheightofthecontour.

Spacingfeatureparameter

ItisexpressedbytheaveragewidthRsmofthecontourelement.Withinthesamplinglength,theaveragevalueoftheprofilemicroscopicunevennessspacing.Themicroscopicunevennessdistancereferstothelengthofthecontourpeakandtheadjacentcontourvalleyonthemidline.

Shapefeatureparameters

ItisexpressedbythecontoursupportlengthratioRmr(c),whichistheratioofthecontoursupportlengthtothesamplinglength.Theprofilesupportlengthisthesumofthelengthofeachsectionoftheprofileobtainedbyinterceptingastraightlineparalleltothecenterlineandadistanceofcfromthetoplineoftheprofilewithinthesamplinglength.

Evaluationbasis

Samplinglength

Samplinglengthlristhelengthofareferencelinerequiredtoevaluatethesurfaceroughness.Thesamplinglengthshouldbeselectedaccordingtotheactualsurfaceformationandtexturecharacteristicsofthepart,andthelengththatcanreflectthecharacteristicsofthesurfaceroughnessshouldbeselected.Thesamplinglengthshouldbemeasuredaccordingtothegeneraltrendoftheactualsurfacecontour.Thepurposeofspecifyingandselectingthesamplinglengthistolimitandreducetheinfluenceofsurfacewavinessandshapeerrorsonthemeasurementresultsofsurfaceroughness.

Evaluationlength

Theevaluationlengthlnisasectionoflengthnecessarytoevaluatethecontour,anditcanincludeoneorseveralsamplinglengths.Becausethesurfaceroughnessofeachpartofthepartsurfaceisnotnecessarilyveryuniform,acertainsurfaceroughnesscharacteristiccannotbereasonablyreflectedinasamplinglength,soitisnecessarytotakeseveralsamplinglengthsonthesurfacetoevaluatethesurfaceroughness.Theevaluationlengthlngenerallyincludes5samplinglengthslr.

Baseline

Thebaselineisthecontourcenterlineusedtoevaluatesurfaceroughnessparameters.Therearetwotypesofreferencelines:

Theleastsquarescenterlineofthecontour:withinthesamplinglength,thesumofthesquaresofthecontouroffsetofeachpointonthecontourlineisthesmallest,andithasageometriccontourshape.

Thearithmeticmeancenterlineofthecontour:withinthesamplinglength,theareaoftheupperandlowercontoursonthecenterlineisequal.

Theoretically,theleastsquaresmidlineistheidealbaseline,butitisdifficulttoobtaininpracticalapplications.Therefore,itisgenerallyreplacedbythearithmeticmeanmidlineofthecontour,anditcanbeusedformeasurement.Replacewithastraightlinewithanapproximatelocation.

Symbolannotation

Surfaceroughnesssymbol

Thenationalstandardstipulatesthatthesurfaceroughnesscodeiscomposedofprescribedsymbolsandrelatedparameters.

1)Surfaceroughnesssymbols

Therearefivesymbolsforsurfaceroughnessonthedrawingaccordingtothenationalstandard,seeFigure1ontheright.

2)Surfaceroughnesscode

Surfaceroughnesscodeisrequiredtobemarkedsuchas:roughnessparametervalue,samplinglengthvalueduringmeasurement,processingtexture,processingmethod,etc.

Themarkingofthesurfaceroughnessonthedrawing

ThedirectionofthecodeandparameterannotationisshowninFigure1.Whenmostpartsofthesurfacehavethesamesurfaceroughness,themostusedsymbolandcodecanbeuniformlymarkedintheupperrightcornerofthedrawing,andtheword"other"shouldbeadded.TheuniformlymarkedcodeandtextheightshouldbemarkedItis1.4timesofthecodeandtextontheothersurfaceofthegraph.

Inthemethodofnotatingsurfacecodesatdifferentpositions,thetipofthesignmustpointfromtheoutsideofthematerialtothesurface,andthedirectionofthenumbersinthecodeisconsistentwiththedirectionofthesizenumbers,asshowninFigure2.

Changemethod

Differentsurfaceroughness

Seethetablebelow

SurfaceFeatures | Surfaceroughness(Ra)value | Exampleofprocessingmethod |

Clearlyvisibletoolmarks | Ra100,Ra50,Ra25, | Roughcar,Roughplaning,roughmilling,drilling |

Slightlyseetoolmarks | Ra12.5.Ra6.3,Ra3.2, | Fineturning,fineplaning,finemilling,roughreaming,roughgrinding |

Noprocessingtracescanbeseen,andtheprocessingdirectionisslightlydiscerned | Ra1.6,Ra0.8,Ra0.4, td> | Fineturning,finegrinding,finereaming,grinding |

Darkglossysurface | Ra0.2,Ra0.1,Ra0.05, | Grinding,honing,superfinishing,polishing |

Measurementmethod

Comparisonmethod

Thecomparativemethodiseasytomeasure.Itisusedforon-sitemeasurementintheworkshop,andisoftenusedformeasurementonmediumorroughsurfaces.Themethodistocomparethemeasuredsurfacewitharoughnessmodelmarkedwithacertainvaluetodeterminethemeasuredsurfaceroughnessvalue.Methodsthatcanbeusedforcomparison:UsevisualinspectionwhenRa>1.6μm,useamagnifyingglasswhenRa1.6~Ra0.4μm,anduseacomparisonmicroscopewhenRa<0.4μm.

Whencomparing,theprocessingmethod,processingtexture,processingdirection,andmaterialofthesamplearerequiredtobethesameasthesurfaceofthetestedpart.

Stylusmethod

Usethediamondstyluswiththetipcurvatureradiusofabout2micronstoslideslowlyalongthemeasuredsurface,andtheupanddowndisplacementofthediamondstylusisconvertedbytheelectricallengthsensorAftertheelectricalsignalisamplified,filtered,andcalculated,thesurfaceroughnessvalueisindicatedbythedisplayinstrument,andarecordercanalsobeusedtorecordtheprofilecurveofthemeasuredsection.Generally,themeasuringtoolthatcanonlydisplaythesurfaceroughnessvalueiscalledthesurfaceroughnessmeasuringinstrument,andthesurfaceroughnessprofilerthatcanrecordthesurfaceprofilecurveatthesametime.Thesetwomeasuringtoolshaveelectroniccalculationcircuitsorelectroniccomputers,whichcanautomaticallycalculatethearithmeticmeandeviationRaofthecontour,theten-pointheightofthemicroscopicunevennessRz,themaximumheightofthecontourRyandothervariousevaluationparameters.ThemeasurementefficiencyishighanditissuitableforMeasurethesurfaceroughnesswithRaof0.025~6.3microns.

Lightsectionmethod

Thedouble-tubemicroscopemeasuressurfaceroughness,whichcanbeusedtoevaluateRyandRzparameters,andthemeasurementrangeis0.5-50.

Interferometry

Usingtheprincipleoflightwaveinterference(seeflatcrystal,laserlengthmeasurementtechnology),theshapeerrorofthemeasuredsurfaceisdisplayedininterferencefringepatterns,andthemagnificationishigh(Upto500times)themicroscopemagnifiesthemicroscopicpartoftheseinterferencefringesandthenmeasuresittoobtainthemeasuredsurfaceroughness.Thesurfaceroughnessmeasurementtoolusingthismethodiscalledaninterferencemicroscope.ThismethodissuitableformeasuringsurfaceroughnesswithRzandRyrangingfrom0.025to0.8microns.

ApplicationPrinciples

Surfaceroughnesshasagreatinfluenceontheuseofparts.Generallyspeaking,asmallsurfaceroughnessvaluewillimprovethequalityofthefit,reducewearandextendtheservicelifeoftheparts,buttheprocessingcostsofthepartswillincrease.Therefore,thesurfaceroughnessvalueshouldbeselectedcorrectlyandreasonably.Whendesigningparts,thechoiceofsurfaceroughnessvalueisdeterminedbythepart'sroleinthemachine.

Thegeneralprincipleistoselectalargersurfaceroughnessvalueunderthepremiseofensuringthatthetechnicalrequirementsaremet.Whenmakingspecificselections,youcanrefertothefollowingprinciples:

(1)Theroughnessvalueoftheworkingsurfaceissmallerthanthatofthenon-workingsurface.

(2)Theroughnessofthefrictionsurfaceissmallerthanthatofthenon-frictionsurface.Thehigherthefrictionspeedofthefrictionsurface,thehighertheunitpressureitreceives,andthehigheritshouldbe;therollingfrictionsurfacerequiresasmallerroughnessvaluethantheslidingfrictionsurface.

(3)Forclearancefits,thesmallerthefitclearance,thesmallertheroughnessvalue;forinterferencefits,inordertoensurethefirmnessandreliabilityoftheconnection,thelargertheload,thesmallertheroughnessvalueisrequired.Generally,theroughnessvalueofclearancefitissmallerthanthatofinterferencefit.

(4)Theroughnessofthematingsurfaceshouldbeequivalenttoitsdimensionalaccuracyrequirements.Whenthematchingpropertiesarethesame,thesmallerthepartsize,thesmallertheroughnessvalueshouldbe;thesameaccuracylevel,thesmallersizehasasmallerroughnessvaluethanthelargesize,andtheshaftratioholehasasmallerroughnessvalue(especiallytheaccuracyofIT8~IT5).

(5)Surfacessubjecttocyclicloading,internalfilletsandrecesseswherestressconcentrationmayoccur,shouldhaveasmallroughnessvalue.

Influencingfactors

Theinfluenceofsurfaceroughnessonpartsismainlymanifestedinthefollowingaspects:

1.Influencingwearresistance.Therougherthesurface,thesmallertheeffectivecontactareabetweenthematingsurfaces,thegreaterthepressure,thegreaterthefrictionalresistance,andthefasterthewear.

2.Affectthestabilityofcoordination.Forclearancefits,therougherthesurface,theeasieritistowear,whichwillgraduallyincreasetheclearanceduringwork.Forinterferencefits,themicroscopicpeaksareflattenedduringassembly,whichreducestheactualeffectiveinterference.Theconnectionstrength.

3.Affectfatiguestrength.Therearelargewavetroughsonthesurfaceofroughparts.Likesharpnotchesandcracks,theyareverysensitivetostressconcentration,therebyaffectingthefatiguestrengthoftheparts.

4.Affectcorrosionresistance.Theroughsurfaceofthepartcaneasilycausecorrosivegasorliquidtopenetrateintothemetalinnerlayerthroughthemicroscopicvalleysonthesurface,causingsurfacecorrosion.

5.Affectthetightness.Roughsurfacescannotbecloselyattached,andgasorliquidleaksthroughthegapsbetweenthecontactsurfaces.

6.Affectcontactstiffness.Contactstiffnessistheabilityofthejointsurfaceoftheparttoresistcontactdeformationundertheactionofexternalforce.Thestiffnessofthemachinedependstoalargeextentonthecontactstiffnessbetweentheparts.

7.Affectmeasurementaccuracy.Thesurfaceroughnessofthemeasuredsurfaceofthepartandthemeasuringsurfaceofthemeasuringtoolwilldirectlyaffecttheaccuracyofthemeasurement,especiallyduringprecisionmeasurement.

Inaddition,thesurfaceroughnesswillhavevaryingdegreesofinfluenceonthecoating,thermalconductivityandcontactresistance,reflectivityandradiationperformanceoftheparts,theresistanceofliquidandgasflow,andtheflowofcurrentontheconductorsurface..

Evaluationbasis

Surfacefinish

Surfacefinishisanothertermforsurfaceroughness.Thesurfacefinishisputforwardaccordingtothehumanvisualpointofview,andthesurfaceroughnessisputforwardaccordingtotheactualsurfacemicro-geometry.Becauseoftheconformitywithinternationalstandards(ISO),Chinaadoptedsurfaceroughnessandabolishedsurfacefinishinthe1980s.AfterthepromulgationofthenationalstandardsforsurfaceroughnessGB3505-83andGB1031-83,thesurfacefinishisnolongerused.

Surfacefinishandsurfaceroughnesshaveacorrespondingcomparisontable.Roughnesshasacalculationformulaformeasurement,whilesmoothnesscanonlybecomparedwithamodelgauge.Therefore,theroughnessismorescientificandrigorousthanthefinish.

Surfacefinishandsurfaceroughnesscomparisontable

Finishness Level (Oldstandard) | Roughness Ra (μm) | 1)Surfacecondition,2)Processingmethodand3)Applicationexamples |

▽1 | 400~800 | |

▽2 | 200~400 | 1)VisibleknifeMark2)Roughturning,boring,planing,drilling3)Surfaceafterroughmachining,2Weldbeforewelding,roughdrillingwall,etc. |

▽3 | 100~200 | 1)Visibletoolmarks2)Roughturning,planing,milling,drilling3)Generalnon-bondingsurfaces,suchasshaftendfaces,chamfers,gearandpulleysidesurfaces,Thenon-workingsurfaceofthekeyway,thesurfaceoftheweight-reducingeyelet |

▽4 | 50~100 | 1)visibleprocessingtraces2)turning,boring,planing,drilling,milling,filing,grinding,roughreaming,milling3)Thematingsurfacesofunimportantparts,suchastheendfacesofpillars,brackets,shells,bushings,shafts,andcovers.Thefreesurfaceofthefastener,thesurfaceofthethroughholeofthefastener,thenon-centeringsurfaceoftheinnerandoutersplines,theroundsurfaceofthegeartopringthatisnotusedasameasurementreference,etc. |

▽5 | 25~50 | 1)Processingtracesareslightlyvisible2)Turning,boring,planing,milling,scraping1to2points/cm^2,drawing,grinding,filing,rolling,milling3)andotherpartsconnectiondoesnotformamatingsurface,Suchastheendfaceofthebox,shell,endcoverandotherparts.Fixedbearingsurfacesthatrequirecenteringandmatchingcharacteristics,suchascenteringshafts,workingsurfacesofkeysandkeyways.Thesurfaceofthefasteningthreadisnotimportant.Thesurfacethatneedsknurlingoroxidationtreatment |

▽6 | 12.5~25 | 1)Cannotseetheprocessingtraces2)Turning,boring,planing,milling,reaming,drawing,grinding,rolling,scraping1~2points/cm^2millingteeth3)InstallthehousingholeoftheG-classbearingwithadiameterofmorethan80mm,thetoothsurfaceoftheordinaryprecisiongear,thepositioningpinhole,thesurfaceoftheV-beltwheel,andtheoutersplinecenteredontheouterdiameterDiameter,thecenteringshouldersurfaceofthebearingcap |

▽7 | 6.3~12.5 | 1)Thedirectioninwhichthemachiningmarkscanbeidentified2)Turning,boring,drawing,grinding,milling,scraping3-10points/cm^2,rolling3)Surfacesthatrequirecenteringandmatchingcharacteristics,suchasthesurfacesoftaperedpinsandcylindricalpins,shaftdiametersandhousingholesmatchingwithG-classprecisionrollingbearings,shaftdiametersanddiametersformedium-speedrotationTheshaftdiameterandhousingholeoftheEandDgraderollingbearingsexceeding80mm,thecenteringinnerdiameteroftheinnerandoutersplines,theoutersplinekeysideandthecenteringouterdiameter,theholeoftheIT7levelofinterferencefit(H7),clearancefitIT8~IT9levelholes(H8,H9),groundgearsurface,etc. |

▽8 | 3.2~6.3 | 1)Micro-identificationofthedirectionofprocessingtraces2)Reaming,grinding,boring,pulling,Scrape3-10points/cm^2,rolling3)Itisrequiredtomaintainastablematingsurfaceforalongtime,IT7-levelshaftandholematingsurface,high-precisiongearsurface,importantpartssubjecttovariablestress,anddiameterTheshaftdiametersurfaceoftheEandDclassbearingssmallerthan80mm,thesurfaceoftheshaftcontactingtherubberseal,theIT13~IT16holeofthesizelargerthan120mm,andthemeasuringsurfaceoftheshaftgauge |

▽9 | 1.6~3.2 | 1)Thedirectionofthemachiningtracescannotbediscerned2)Wheelgrinding,grinding,grinding,superprocessing3)Thesurfaceofimportantpartssubjecttovariablestressduringwork.Ensurethefatiguestrength,corrosionresistanceanddurabilityoftheparts,anddonotdamagethematingsurfaceduringwork,suchastheshaftdiametersurface,theairtightsurfaceandthesupportingsurface,andtheconicalcenteringsurface.IT5,IT6levelmatingsurface,surfaceofhigh-precisiongear,shaftdiametersurfacematchedwithG-levelrollingbearing,IT7~IT9levelholewithsizegreaterthan315mmandshaftgaugelevelIT10~IT12holewithsizegreaterthan120~315mmMeasuringsurfaceofshaftgauges,etc. |

▽10 | 0.8~1.6 | 1)Darkglossysurface2)Superprocessing3)Thesurfaceofimportantpartsthataresubjectedtogreatervariablestressduringwork.Ensurethatthesurfaceoftheconeispreciselycentered.Holesurfaceforhydraulictransmission.Theinnersurfaceofthecylinderliner,theoutersurfaceofthepistonpin,theguiderailsurfaceoftheinstrument,theworkingsurfaceofthevalve.IT10~IT12gradeholeandshaftgaugemeasuringsurfacewithsizelessthan120mm,etc. |

▽11 | ||

▽11 | 0.4~0.8 | |

▽12 | 0.2~0.4 | |

▽13 | 0.1~0.2 | |

▽14 |

Latest: megahertz

Next: Microphone