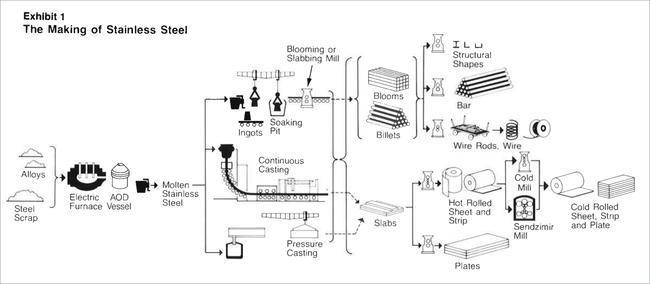

Stainless steel processing

Concept

Stainless steel processing equipment is classified into a shear device and surface treatment equipment, and it is divided into open equipment and minute equipment in shearing equipment. In addition, from the thickness of stainless steel, there is a cold-rolled processing equipment in the thickness of stainless steel. The heat cutting equipment mainly has plasma cutting, laser cutting, water cutting, etc.

Surface processing grade

Original: NO.1 hot rolling surface after hot rolling surface. Generally used for cold rolling materials, industrial tanks, chemical industrial equipment, etc., thick thickness consists of 2.0 mm to 8.0 mm.

blunt surface: No. 2D After heat treatment, the heat treatment is soft, the material is soft, and the surface is silver white luster for deep punching, such as automotive components, water pipes, etc.

fog surface: No. 2b After cold rolling, heat treatment, pickling, and then the surface is a moderate light. Due to smooth surface, it is easy to ground, making the surface more shining, widely used, such as tableware, building materials, etc. After the surface treatment of improved mechanical properties, almost all uses.

Coarse sand No. 3 Grinding the product from 100-120. It has better gloss, with discontinuous roughness. Used in building inside and outside decorative materials, electrical products and kitchen equipment.

fine sand: No.4 Products with particle size 150-180 grinding. It has better gloss, with discontinuous roughness, stripe ratio No.3 fine. For bath, building inside and outside decorative materials, electrical products, kitchen equipment and food equipment.

# 320 is grinded with the 320 grinding. It has better gloss, with discontinuous roughness, stripes ratio No.4. For bath, building inside and outside decorative materials, electrical products, kitchen equipment and food equipment.

Filament Hairline: HLNO.4 is continuously grinded by a suitable granular polished abrasive strap to generate grinding pattern (segmentation 150-320). Mainly used in architectural decoration, elevators, buildings, panels, etc.

Highlights: BA is applied to the bright annealing after cold rolling and the product is obtained. The surface gloss is extremely good, with a high reflectivity. Like the surface of the mirror. For home appliances, mirrors, kitchen equipment, decorative materials, etc.

Latest: Why don't you socialism?

Next: Solar radiation