Servo control system

Basic Release

The servo control system is an operating system that automatically controls the mechanical movement of the test device in accordance with the predetermined requirements. In many cases, the servo system is specifically referred to as being controlled (the output of the system) is a mechanical displacement or displacement speed, the acceleration feedback control system, its function is to accurately track the input displacement ( Or corner). The structure composition of the servo system and other forms of feedback control systems have no principles.

Main indicators

Measuring the main indicator system accuracy, stability, response characteristics, and operating frequency of servo control system performance, particularly in terms of band width and accuracy.

The bandwidth of the bandwidth is defined by the system frequency response characteristics, reflecting the rapidity of the tracking of the servo system. The larger the bandwidth, the better the rapidness. The bandwidth of the servo system is mainly limited by the inertia of the control object and the actuator. The larger the inertia, the narrower the bandwidth. Generally, the bandwidth of the servo system is less than 15 hzes, and the bandwidth of the large device servo system is below 1 to 2 H. Since the 1970s, due to the development of torque motor and high sensitivity speed measuring machine, the servo system achieved direct driving, leather or decreased nonlinear factors such as gap and elastic deformation, so that the bandwidth reached 50 hz, and successfully applied At remote missiles, artificial satellites, precision commanders and other places. The accuracy of the servo system is primarily determined to the accuracy of the measurement element used. Therefore, high-precision measuring elements such as precision potentiometers, self-angle machines and rotary transformers, must be employed in the servo system. In addition, additional measures can also be taken to improve the accuracy of the system, such as connecting the measurement shaft of the measuring element (such as self-angle) to the rotor, so that the rotation angle of the rotating shaft is enlarged to improve the relative measurement accuracy. A servo system using this scheme is called a refined test system or a dual channel system. The angular read passage is directly taken from the angular read passage of the angle of rotation to the angle-engaged angle line.

Structure Composition

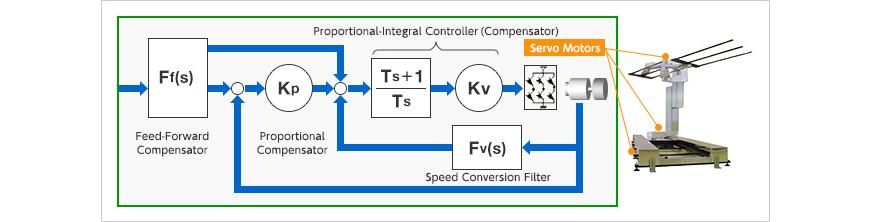

The structure of the servo control system of the machine, there are many types, but from the perspective of automatic control theory, the servo control system generally includes controllers, controlled objects , Execution links, detection links, comparison links and other five parts.

Comparison link

The comparison link is compared to the input instruction signal with the feedback signal of the system to obtain a link to the deviation signal between the output, usually by a special circuit or Computer is implemented.

Controller

The controller is typically a computer or PID control circuit, and its main task is to transform the deviation signal output from the comparison element to control the execution element as required.

Execution link

Performing the function is to convert the various forms of energy into mechanical energy, drive the controlled object in the requirements of the control signal. Mechanical and electrical integration system Executive elements generally refer to a variety of motors or hydraulic, pneumatic servo mechanisms, and the like.

Controlled objects

The number of mechanical parameters includes displacement, speed, acceleration, force, and torque as a controlled object.

Detection Assembly

Detection As a device capable of measuring and converting to the output, a sensor and a conversion circuit are typically included.

System classification

The classification method of the servo system is much, the common classification method has the following three types.

(1) Classified by the control parameter feature.

(2) Classification by the type of drive element.

The servo control system can be divided into electromechanical servo system, hydraulic servo system (hydraulic control system) and pneumatic according to the type of control element used. server system.

(3) Classified by control.

The servo system can be divided into open-loop control servo system, closed loop control servo system, and semi-closed loop control servo system.

Common four servo control systems are as follows:

(1) Hydraulic servo control system

hydraulic servo control system provides power based by motor, using hydraulic pressure The pump converts mechanical energy into pressure to push hydraulic oil. By controlling the flow of hydraulic oil by controlling various valves, the hydraulic cylinder is pushed to make different travels, different directions, and complete different action needs of various devices. The hydraulic servo control system is obtained in accordance with the deviation signal, which is divided into a machine-liquid, electrical-liquid, gas-liquid, etc., which is used in the application of the machine-liquid and electrical-liquid control system. According to the amount of physical quantity, the hydraulic servo control system can be divided into position control, speed control, force control, acceleration control, pressure control, and other physical quantity control. The hydraulic control system can also be divided into throttling control (valve control) type and volume control (pump control). In mechanical equipment, primary organic-liquid servo systems and electrical-liquid servo systems.

(2) AC servo control system

AC servo control system includes an AC servo system based on asynchronous motors and an AC servo system based on synchronous motors. In addition to having a good stability, good rapidity, high precision, has a series of advantages. Its performance indicators can be measured from aspects of speed control range, positioning accuracy, steady speed, dynamic response, and operation stability.

(3) DC servo control system

The working principle of the AC servo control system is based on electromagnetic law. The electromagnetic torque is related to each other two variable main magnetic flux and armature current, which control the excitation current from the armature current, which can easily control the torque and speed control. On the other hand, from the control perspective, the control of DC servo is a single variable control system output by a single input single output. The classic control theory is fully applicable to such a system. Therefore, it is simple to control, and the speed control performance is excellent in CNC machine tools. The feed is dominated in the driving.

(4) Electro-hydraulic servo control system

It is a feedback control system composed of an electrical signal processing device and a hydraulic power mechanism. The most common electro-hydraulic position servo system, electrohytic velocity control system, and electroless (or torque) control system.

The above is the four servo systems that we are using, their working principle and performance, and the scope of application can be applied, each has its own characteristics and advantages and disadvantages. Therefore, when choosing or purchasing, it is necessary to select the appropriate product after calculation according to the needs of the system and the need to control.

Technical requirements

1. System accuracy

Servo system accuracy refers to the accuracy of the output volume recurring input signal requirements, in the form of errors, It can be summarized as three aspects of dynamic errors, steady state errors and static errors.

2. Stability

The stability of the servo system means that after the action on the system disappears, the system can restore the power of the original steady state; or After the new input instruction, the system reaches the ability to stabilize the status.

3. Response characteristics

Response characteristics refer to the output of the output follow the input command change, determine the working efficiency of the system. Response speed is related to many factors, such as computer Running speed, damping and quality of motion systems.

4. Working frequency

The operating frequency is usually referred to as the frequency range of the system allows the input signal. When the operating frequency signal is input, the system can work normally according to the technical requirements; while other frequency signals When entering, the system cannot work properly.

Application

The servo control system initially used for automatic driving, artillery control and commander, and later gradually promoted to many fields, especially automatic lathes, antenna location control, missiles Guidance for spacecraft, etc.

The servo system is mainly to achieve the following purposes:

1 to control the high power load with a small power command signal. The artillery control and rudder control are typical examples.

2 In the case where there is no mechanical connection, the input shaft is controlled from the output shaft at a distance to achieve a remote synchronous transmission.

3 makes the output mechanical displacement accurately track the electrical signal, such as recording and instruction instrumentation.

Latest: 1024 programmer festival