Product configuration

Definition Management

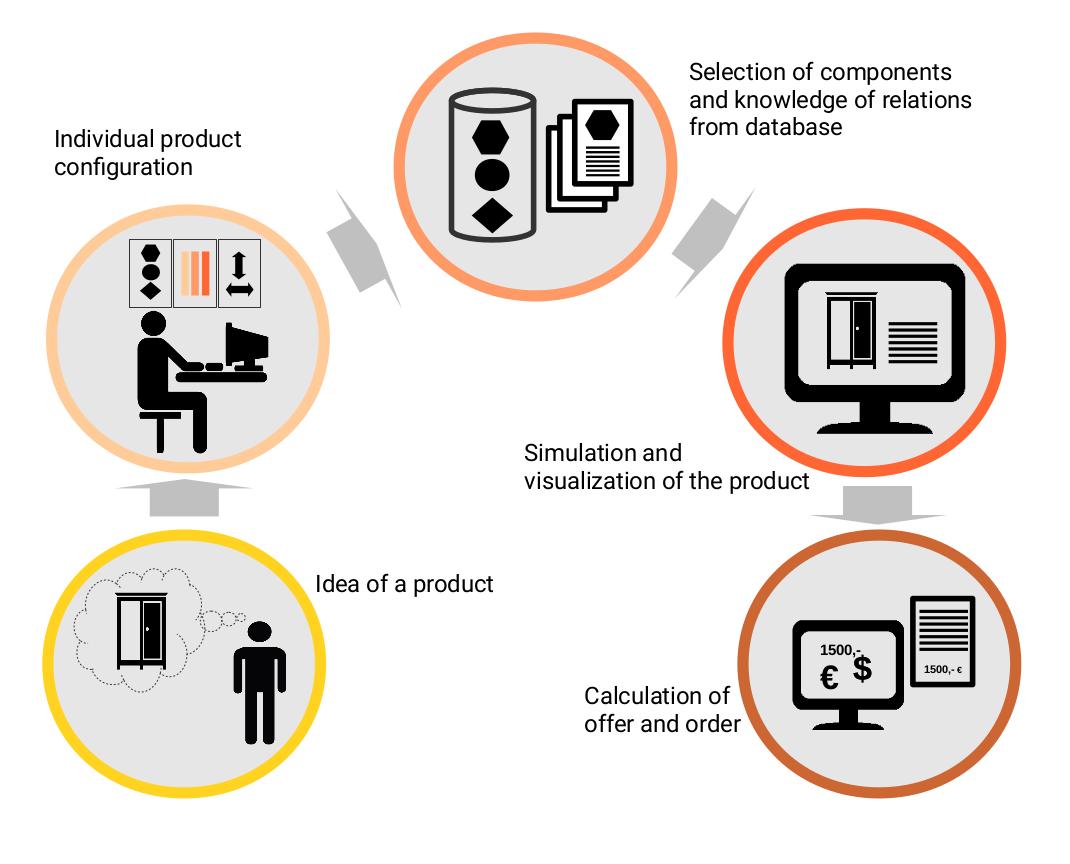

Product configuration is all data defined by product, including geometric model information, analysis results, technical description, process file, contract order and quality file, etc. It has been established, and the user can clearly and conveniently know the impact of a change. Product configuration management spirit is a generalized material list of material listings (BM) management, the product configuration management system can generate material list, and can be configured according to the rules specified by the user.

Product Configuration Management PCM (Product Configure Management) is supported by the data warehouse, using the material list to organize the core, link all the engineering data and documents of the final product to the organization of product data. , Control and management, and provide different views and descriptions of the product structure to the user or application system under constraints of certain objectives or rules, and also provide basic information services for many other systems (such as ERP, CRM, etc.).

In order to achieve organic combination of product structure and product configuration, a practical management method-product configuration management, enabling it to modern enterprise management ERP, achieve fast, efficient integration To provide customers with a rapid response market to provide personalized products, product structure management generally manages and describes product structures through a variety of different divisions. Each BOM is a management object, and the view object can be transmitted according to certain rules. Each component can be associated with a plurality of views, which can generate different views from the composite data structure of the same product. Figure 1 is a schematic diagram of the product structure multi-view conversion.

Enterprise Application

During the production process, for different products, due to its characteristics, use, materials, structural complexity and precision level, manufacturing production organization is also different. . Product configuration management is best for companies that apply to multi-variety, small batch and discrete production types. Definition of production types and the characteristics of company products and methods of production.

The method of product configuration management can be configured in accordance with the distribution of components, and can also be configured in variables and rules and components.

Anhui Forklift Group Company uses the EMS management system introduced from the US EMS, the product configuration function module name is a product configurator (referred to as F / O). F / O The BOM of the product is configured according to variables and rules, making "manufacturing for personalized demand" more easily. This configuration provides a larger configuration freedom, and implements the configured customization ideas.

The product model can often be determined by several critical parameters, so these key parameters constitute a configuration variable, and we call the feature in the EMS system. The description of these variables (features) is called an option. The process of product configuration is actually by selecting different variables (features) and variables, thereby obtaining the process of corresponding product BOM configurations. Of course, it is also necessary to construct a configuration engineer in which the F / O table defines a certain constraint condition (logical relationship definition) to make the managers who do not understand the technical details configured in accordance with the user requirements.

The product composite data structure and the F / O table form an information unit, and the product composite data structure gives the most complete product structure, and the F / O table stores specific configuration selection rules and selection logic. . Therefore, the product composite data structure and the F / O table provide a means - by defining a series of key parameters, the product is configured to generate BOM. The customer here is not just a sales customer of the terminal, where more is the user who uses product configuration features within the company.

Facing thousands of varieties produced by the company, responsible for building an engineer of the F / O table must be familiar with the structure of all products and the intrinsic logic relationship of parent and child in the product structure, and in this basis The appropriate features and options make up the corresponding features and options, and must define all product logic relationships based on the understanding of the product, providing users with a reasonable product configuration. Our F / O tables built in the EMS system covers a variety of products such as 1-16 tons of internal burning forklifts, battery cars, loaders, stacking machines.

In the process of building an F / O table, the configuration engineers not only need to repeatedly check the product drawings, process documents, and other technical documents related to the product, but also need to manage the same technicians, data management personnel and other sectoral management. People exchange communication to determine the best solution. Therefore, a reasonable and accurate F / O is the crystallization of collective wisdom.

The product configuration function is mainly used to plan (self-made planning and purchasing plans), the production of workshop orders, is the faucet of planning and production organization, play a crucial role. If the F / O table builds unreasonable (including logical relationship is not accurate), it cannot provide users with a reasonable product configuration. Users cannot get accurate data, and enterprise production cannot be effectively organized, which will bring the company's plans and production. Unforeseen losses and effects. That is why product configuration management is "soul" of modern enterprise management erp.

Latest: designer