Magnetic generator

History

The first person who produces high-voltage magnetic generator ideas is Andre Boudeville, but the capacitor is ignored in his design; Frederick SIMMS and Robert Bosch have developed The first available high voltage magnetic generator.

Magnetic generator is used by Daimlerphönix car companies in 1899. Subsequently by Mercedes, Mercedes, MORS, TURCAT-MERY, AndNESSELDORF, and soon, most vehicles were used in low pressure (voltage by the secondary coils) and high pressure (directly ignited spark plug, similar to the coil ignition, Bochi introduced in 1903) Magnetic power concentration until 1918.

Operation

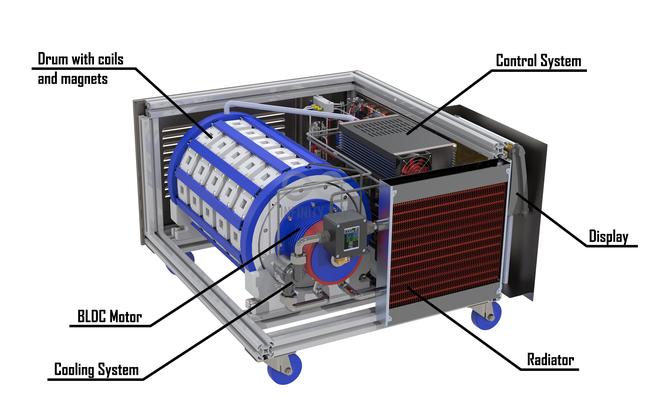

is called the type of shuttle magnetic generator, and the engine drives the wire coil to rotate around the two poles of the magnet. In the induction magnetic generator , the magnet rotates and the coil remains stationary.

Turn, the cam is turned on, the cam is turned on, and the interrupt generates a current generating an electromagnetic field in the original coil. When the magnetic field disappears, the voltage is generated (such as the Larami Sub-magnetic induction law) on the original coil. When these contacts are opened, the contact spacing means that the voltage on the original coil will across these points. Place the capacitor on these points to calm the voltage on the arc, the original coil, and control the electrical energy dissipation rate on the original coil.

is more than the secondary coil of the original coil, and wire is wound on the same core to form an electrical transformer. The ratio ratio ratio of the wound coil of the secondary coil and the original coil is called the number of turns ratio . The voltage on the original coil is enlarged to the secondary coil in this ratio. The ratio of turns ratio between the original sub-coil is used, because this can make the voltage on the secondary coil reach a very high value, thereby sufficient arc spacing between the spacing between the spark plug.

Air

Because it does not require a battery or other form of energy, the magnetic generator is a small and reliable self-sufficiency system, so it is still used in many general aviation applications.

The aircraft engine of the magnetic power generation device is a typical double plug , which is two spark plugs in each cylinder, each plug, has a separate magnetic power generation system. Such arrangements provide a replacement for the damage of any magnetic generator. Double sparks provide a double flame in the cylinder. These two flames have reduced the time required to complete the fuel supplement and ignition, so most fuels are already in combustion under a relatively low temperature and pressure. As the combustion pressure in a separate cylinder is raised, the mixed fuel of lower proportion of octane can be distorted at the front of the other flame in the other side of the gas cylinder on the other side of the gas cylinder on the other side of the gas cylinder at the front of the initial flame. This will cause the engine's oscillation. Therefore, the front of the double flame helps to reduce any given engine and the need for octane. This is very important for most large diameter aircraft engines developed during the Second World War.

Some aircraft engines and some old-fashioned high-end cars have used Shuangli systems and a spark plug that is ignited by magnetic power generation, and another set of connectors to coils, generators, and battery circuits. This effectively improves the efficiency of the engine and does not reduce credibility. The magnetic generator once considered a more reliable ignition source, but there is a fixed time selection defect. This means that the time selection must be a compromise setting, not the best time for the lowest and maximum RPM (speed per minute). On the other hand, the battery ignition system has an advanced time to select the impact, and the optimal time selection can be set according to the engine speed, improve the output power and fuel utilization. As the reliability of the battery ignition system is improved, the magnetic power generation device exits the field of automobile applications.

The modern engine has a smaller combustion chamber and fewer oscillation, because the modern engine is designed to eliminate the hot region in the cylinder. Such a combustion chamber reduces the need for octane due to its shape and eddy current input. Therefore, they no longer need a double plug to reduce the need for octane. Harley motorcycle engine has a single fork, cooling the air, and has a huge "old" combustion room design, still benefit from the double spark plug. For most of the capacity and fuel-type tensioning engine, its engine design (most of the 1960s-based Chrysler HEMI engine) requires an additional flame center to use most fuel injected in the injection period. .

Phone

Many early manual phones have a hand-movable "magnetic power generation" device to generate (relatively) high-voltage replacement signals to make other telephones (part) Ringing and call the operator. These have been used for remote rural lines that are manually operated, due to their lack of "shared batteries". Telephone equipment has been "local batteries", including two large "six" carbon-zinc dry batteries.

See

-

ignition system

Latest: Souvenirs

Next: And Long Basin