laser technology

Principle

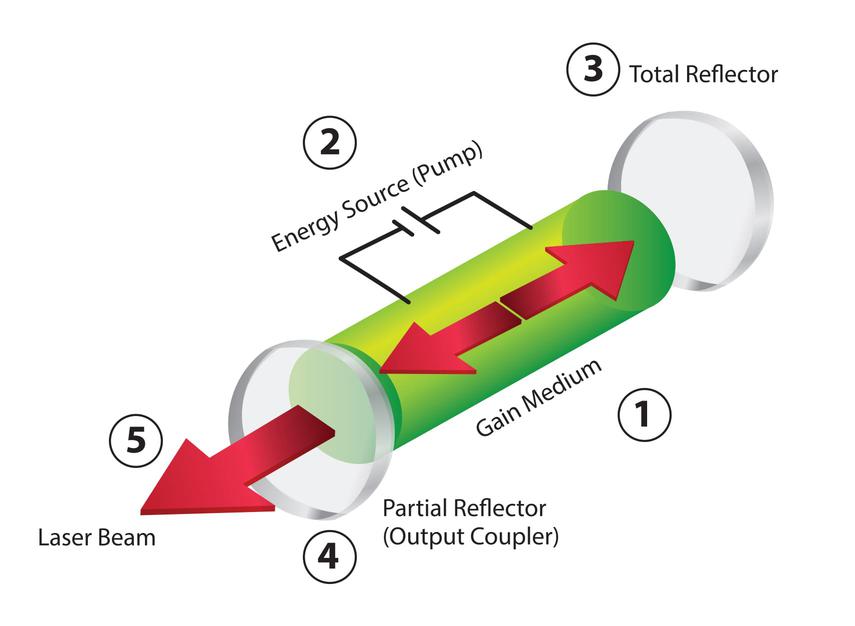

ThefullEnglishnameoflaserisLightAmplificationbyStimulatedEmissionofRadiation(LASER).Introducedin1960,itisakindoflightthatisenhancedbystimulatingradiation.Theprincipleistousethered,green,andbluelasersasthelightsource,anddisplaybyadjustingtheintensityratio,totalintensity,andintensityspatialandtemporaldistributionofthethree-colorlasers.

Scientistsusetheenergyoflightorelectriccurrenttohitcertaincrystalsoratomsthataresusceptibletoexcitation,sothattheelectronsoftheatomsreachtheexcitedhigh-energystate.WhentheseelectronsreturntoInacalmlow-energystate,atomswillemitphotonstoreleaseexcessenergy;andthen,theseemittedphotonswillhitotheratoms,excitingmoreatomstoproducephotons,triggeringaseriesof"chainreactions",andTheyallmoveinthesamedirection,formingastrongandconcentratedlightinacertaindirection;therefore,astronglasercanevenbeusedtocutsteelplates!

ThetheoreticalbasisoflaseroriginatedfromphysicistEinstein.In1917,Einsteinproposedanewsetoftechnicaltheory"theinteractionoflightandmatter".Thistheoryisthatintheatomsthatmakeupmatter,therearedifferentnumbersofparticles(electrons)distributedatdifferentenergylevels.Particlesathighenergylevelsareexcitedbyacertainphoton,andtheywilljump(transition)fromthehighenergyleveltoAtalowenergylevel,lightofthesamenatureasthelightthatexcitesitwillberadiatedatthistime,andinacertainstate,aweaklightcanexciteastronglight.Thisiscalled"lightamplificationbystimulatedradiation",orlaserforshort.

Liquid,gasandsolidcanallproducelaserlight.Thegasesincludeargon,carbondioxide,andorganicdyesinliquids.Theso-calledsolid-statelaseristhelasergeneratedinthesolid,suchaslasercrystal,laserceramic,andlaserglass.Unlikegaslasers,solid-statelasersarenon-flowing,smallinsize,andhighlyefficient.Now,thewavelengthofthesolid-statelasercanbechanged,thatis,itcanbetuned.

Nowweareenteringtheeraofartificialintelligence.Inthisera,lasersareanindispensabletool,orameans.Forexample,ifthesweepingrobotisequippedwithlidar,itcanhavebetterperformanceinobstacleavoidanceandintelligence,andcanefficientlycompletethecleaningoftheentirehouseintheshortesttime.

Application

Laserprocessingtechnology

SpacecontroloflaserIthasgoodperformanceandtimecontrol,andithasgreatfreedomforthematerial,shape,sizeandprocessingenvironmentoftheprocessingobject.Itisespeciallysuitableforautomatedprocessing.Thecombinationoflaserprocessingsystemandcomputernumericalcontroltechnologycanformhigh-efficiencyautomaticprocessingequipment,whichhasbecomeakeytechnologyforenterprisestoimplementtimelyproduction,openingupabroadprospectforhigh-quality,efficientandlow-costprocessingandproduction.

Heatprocessingandcoldprocessingcanbeappliedtometalandnon-metalmaterials,forcutting,perforating,notching,marking,etc.Hotprocessingmetalmaterialsforwelding,surfacetreatment,alloyproduction,cuttingareextremelyadvantageous.Coldprocessingissuitableforphotochemicaldeposition,laserrapidprototypingtechnology,laseretching,dopingandoxidation.

Laserrapidprototyping

ThematerialusedtomakethemodelwithlaserisliquidphotosensitiveresinAfterabsorbingthelaserenergyintheultravioletband,itsolidifiesandchangesintoasolidmaterial.Programthemodeltobemanufacturedandinputitintothecomputer.Thelaserbeamoutputfromthelaseriscontrolledbythecomputeropticalpathsystemsothatitscansandscribesonthemodelmaterial.Wherethelaserbeamreaches,theoriginalliquidmaterialsolidifies.Thelaserbeamscansandscribesunderthecommandofthecomputer,solidifiesthephotosensitivepolymermateriallayerbylayer,andaccuratelystacksthemintosamplestocreateamodel.Therefore,usingthismethodtomakemodelsisfast,andthemodelsmadeareexquisite.Thistechnologyhasbeenwidelyusedinaerospace,electronics,automotiveandotherindustrialfields.

Lasercutting

Lasercuttingtechnologyiswidelyusedintheprocessingofmetalandnon-metalmaterialsInthisway,theprocessingtimecanbegreatlyreduced,theprocessingcostcanbereduced,andthequalityoftheworkpiececanbeimproved.Pulsedlasersaresuitableformetallicmaterials,andcontinuouslasersaresuitablefornon-metallicmaterials.Thelatterisanimportantapplicationfieldoflasercuttingtechnology.However,theapplicationoflasersintheindustrialfieldhaslimitationsandshortcomings.Forexample,theuseoflaserstocutfoodandplywoodisunsuccessful.Thefoodiscutandburnedatthesametime,andcuttingplywoodisfarfromeconomical.

Withtherapiddevelopmentofthelaserindustry,relatedlasertechnologyandlaserproductsarebecomingmoremature.Inthefieldoflasercuttingmachines.TheYAGsolid-statelasercuttingmachineandCO2lasercuttingmachinearebothpowerful,andthefiberlasercuttingmachineiscomingfrombehind.

YAGsolid-statelasercuttingmachinehasthecharacteristicsoflowpriceandgoodstability,buttheenergyefficiencyisgenerally<3%.Theoutputpoweroftheproductismostlybelow600W.Duetothesmalloutputenergy,itismainlyusedforpunching,spotweldingandthinplatecutting.Itsgreenlaserbeamcanbeappliedunderpulseorcontinuouswaveconditions.Ithasshortwavelengthandgoodlightconcentration.Itissuitableforprecisionmachining,especiallyforholemachiningunderpulse.Itcanalsobeusedforcutting,weldingandlithography,etc..ThewavelengthofYAGsolidlasercuttingmachinelaserisnoteasilyabsorbedbynon-metal,soitcannotcutnon-metalmaterials.WhatYAGsolidlasercuttingmachineneedstosolveistoimprovethestabilityandlifeofthepowersupply,thatis,todevelopalarge-capacity,long-lifeopticalpumpExcitationlightsources,suchastheuseofsemiconductorlightpumps,cangreatlyincreasetheenergyefficiency.

CO2lasercuttingmachine,itcanstablycutcarbonsteelwithin20mm,stainlesssteelwithin10mm,andaluminumalloybelow8mm.TheCO2laserhasawavelengthof10.6um,whichisrelativelyeasytobeabsorbedbynon-metals.Itcancutnon-metalmaterialssuchaswood,acrylic,PP,andorganicglasswithhighquality,butthephotoelectricconversionrateoftheCO2laserisonlyabout10%.TheCO2lasercuttingmachineisequippedwithanozzleforblowingoxygen,compressedairorinertgasN2atthebeamexittoimprovethecuttingspeedandthesmoothnessofthecut.Inordertoimprovethestabilityandlifeofthepowersupply,thedischargestabilityofthehigh-powerlasermustbesolvedfortheCO2gaslaser.Accordingtointernationalsafetystandards,thelaserhazardlevelisdividedinto4levels,andtheCO2laseristheleasthazardouslevel.

FiberlasercuttingmachineBecauseitcantransmitthroughopticalfiber,thedegreeofflexibilityisunprecedentedlyimproved,therearefewfailurepoints,maintenanceisconvenient,andthespeedisextremelyfast.Therefore,theopticalfiberisusedwhencuttingthinplateswithin4mm.Thecuttingmachinehasgreatadvantages;however,itisofpoorqualitywhencuttingthickplatesduetothewavelengthofthesolidlaser.Thewavelengthofthefiberlaserlasercuttingmachineis1.06um,whichisnoteasilyabsorbedbynon-metal,soitcannotcutnon-metalmaterials.Thephotoelectricconversionrateoffiberlaserisashighas25%,andtheadvantagesoffiberlaserintermsofelectricityconsumptionandsupportingcoolingsystemarequiteobvious.Accordingtointernationalsafetystandards,laserhazardlevelsaredividedintofourlevels.Fiberlasersarethemostharmfultothehumanbodyduetotheirshortwavelength,whichisthemostharmfultotheeyes.Forsafetyreasons,fiberlaserprocessingrequiresacompletelyenclosedenvironment.Asanemerginglasertechnology,fiberlasercuttingmachineisfarlesspopularthanCO2lasercuttingmachine.

Laserwelding

Whenthelaserbeamshinesonthematerial,itwillbeheatedtomeltWeldingistojointhecomponentsthatarebutttogether,thatis,welding.Inlaserwelding,alaserbeamwithalowerpowerthanwhencuttingmetalisusedtomeltthematerialwithoutvaporizingitandbecomeacontinuoussolidstructureaftercooling.Laserweldingtechnologyhasabathpurificationeffect,cancleantheweldmetal,andissuitableforweldingbetweenthesameanddifferentmetalmaterials.Duetothehighenergydensityofthelaser,itisparticularlyadvantageousformetalweldingwithhighmeltingpoint,highreflectivity,highthermalconductivityandverydifferentphysicalproperties.Becauselaserweldingdoesnotrequireanysolder,iteliminatesthepossibilityofweldingcomponentsbeingcontaminated;secondly,thelaserbeamcanbecondensedbytheopticalsystemintoabeamwithaverysmalldiameter.Inotherwords,thelasercanbemadeintoaveryfineweldinggunforprecisionwelding.Work;andlaserweldingdoesnotdirectlycontactthecomponents,thatis,thisisnon-contactwelding,sothematerialisfragileandnottight.Itcanalsoweldcomponentsfarawayfromus,orputcomponentsinavacuumchamber.Solderitup.Becauseofthesecharacteristics,laserweldingisespeciallypopularinthemicroelectronicsindustry.

Laserengraving

UsingalaserengravingknifeforengravingisbetterthanusinganordinaryengravingknifeConvenientandfaster.Carvingonhardmaterialswithordinarycarvingknife,suchasgraniteorsteelplate,oronsomesoftermaterials,suchasleather,ismoredifficult,andittakesalongtimetocarveapattern..Iflaserengravingisused,itisdifferent,becauseitisanengravingmethodthatusesahigh-energydensitylasertolocallyirradiatetheworkpiecetovaporizethesurfacematerialorcauseachemicalreactiontochangethecolor,therebyleavingapermanentmark.Itisnotincontactwiththematerialatall.Thematerialishardorsoft,whichdoesnothinderthespeedofengraving.Therefore,laserengravingtechnologyisoneofthelargestapplicationareasoflaserprocessing.Withthiskindofcarvingknife,thespeedofcarvingisthesameregardlessofwhetheritiscarvingonahardmaterialorasoftmaterial.Ifitismatchedwithacomputertocontrolthemovementofthelaserbeam,theengravingworkcanalsobeautomated.Putthepatterntobeengravedonthephotoelectricscanner.Afterthesignaloutputbythescannerisprocessedbythecomputer,itisusedtocontroltheactionofthelaserbeam,anditcanbeautomaticallyengravedonthewood,glass,andleatheraccordingtoourpattern.Atthesametime,thefocusedlaserbeamisverythin,whichisequivalenttoaverysmartengravingknife.Theengravinglinesarethinandthedetailsonthepatterncanalsobeengraved.Laserengravingcanproduceavarietyofcharacters,symbolsandpatterns,etc.,andthesizeofthecharacterscanrangefrommillimeterstomicrometers,whichhasspecialsignificancefortheanti-counterfeitingofproducts.Laserengravinghasbeendevelopedtoachievesub-micronengraving,andhasbeenwidelyusedinthemicroelectronicsindustryandbiologicalengineering.

Laserdrilling

Itisverycommontomakeasmallholeinthecomponentthing.However,ifitisrequiredtomakealargenumberofsmallholeswithadiameterof0.1mmtoseveralmicrometersinahardalloy,forexample,ahardmaterial.Iamafraiditisnoteasytodowithordinarymachiningtools.Evenifitcanbedone,theprocessingcostwillbeveryhigh.Thelaserhasgoodcoherence,andtheopticalsystemcanfocusitintoalightspotwithaverysmalldiameter(lessthanonemicron),whichisequivalenttoamicrodrillusedfordrilling.Secondly,thebrightnessofthelaserisveryhigh,andthelaserenergydensity(averageenergypersquaremeterarea)atthefocusedfocalpointwillbeveryhigh.Theenergygeneratedbyacommonlasercanbeashighas109Joules/cm2.Itisenoughtomeltandvaporizethematerial,leavingasmallholeinthematerial,justlikeadrill.However,thelaser-drilledholeisconicalratherthanmechanicallydrilledcylindrical,whichisveryinconvenientinsomeplaces.

Laseretching

Laseretchingtechnologyissimplerandmorereliablethantraditionalchemicaletchingtechnology.Theproductioncostisgreatlyreduced,andthelinewithawidthof0.125to1microncanbeprocessed,whichisverysuitableforthemanufactureofverylarge-scaleintegratedcircuits.

Lasersurgery

Lasercanproducehigh-energy,precisefocusedmonochromaticlight,Ithasacertaindegreeofpenetratingpowerandcangeneratehighheatlocallywhenitactsonhumantissues.Lasersurgeryistousethisfeatureoflasertoremoveordestroythetargettissuetoachievethepurposeoftreatment.Mainlyincludelasercuttingandlaserskinresurfacing.

Laserweapon

Laserweaponhasitsuniqueness,whichmakesitwidelyusedForairdefense,anti-tank,bomberself-defenseandothermilitarypurposes.Thereasonwhylasercanbecomeapowerfulweaponisbecauseithasthreelevelsofdestructivecapabilities:1.Theablationeffectisthesameastheprincipleoflaserthermalprocessing.Whenthehigh-energylaserbeamhitsthetarget,theenergyofthelaserwillbeabsorbedbythetargetmaterialandconvertedintoheatenergy.Theheatenergyisenoughtomakethetargetpartiallyorcompletelyperforate,fracture,melt,evaporate,andevenexplode.

2.Shockwaveeffect.Ifthetargetmaterialisvaporized,thetargetmaterialwillhavearecoileffectinaveryshorttime,formingacompressionwavetocrackthesurfacelayerofthematerial,andcausefurtherdamagewhenthefragmentsflyout.

3.RadiationeffectWhenthetargetmaterialisvaporized,aplasmacloudwillbeformed,whichcangenerateradiantultravioletraysandX-rays,whichwilldestroytheelectronicpartsinsidethetarget.

Laserenergy

Lasercanalsobeappliedtonuclearpowergeneration.Thenuclearfuelusedinnuclearpowerstationsbuiltintheworldisuranium,andresearchontheuseoftritiumfuelhasnotbeensuccessful.Accordingtoresearchfindings,tritonfuelismoreresistanttoburningthanuraniumnuclearfuel,andtheenergyproducedbythecombustionof1kilogramoftritonfuelismorethanthreetimeshigherthanthatofuraniumnuclearfuel.Whatismoreattractiveisthelargereservesoftritonfuelontheearth.Onekilogramofseawatercontains0.03gramsoftritium,andthereare1021kilogramsofseawaterintheoceansoftheearth;inotherwords,thereare1017kilogramsoftritiumstoredintheoceansoftheearth.Ifitisdevelopedforfuel,itisequivalenttoprovidinguswith10Trillions(1017)tonsofcoalareenoughforhumanstouseforhundredsofmillionsofyears.Sincetritonfuelissogood,whynotuseit?Theproblemisthatitisnoteasytoigniteit.Theburningtemperatureofamatchcansetapieceofpaperandgasolineonfire.Tomakethisnuclearfuelignite,ahightemperatureof100milliondegreesisrequired.Laseristhetechnologythatismorelikelytoreachthisignitiontemperature.

Appareluse

Laserembroideryforready-to-wear

Morethantwo-thirdsoftextileandapparelfabricscanuselaserstomakevariousdigitalpatterns.Thetraditionaltextilefabricproductionprocessrequirespost-grinding,hotembossing,embossingandotherprocessingtreatments.Inthisrespect,laserburninghastheadvantagesofconvenientandfastproduction,flexiblepatternchange,clearimages,strongthree-dimensionality,andcanfullyexpressvariousThenaturaltextureofthefabric,andtheadvantagesoflong-lastingandnew.Ifcombinedwiththehollowingprocess,itisthefinishingtouchandcomplementseachother.

Laserembroideryforapparelfabricsandready-madegarmentsissuitablefor:textilefabricfinishingprocessingplants,fabricdeepprocessingplants,ready-madegarmentgarmentplants,surfaceaccessoriesandprocessingenterpriseswithsuppliedmaterials.

Denimimagespraying

Thedyeonthesurfaceofthedenimfabricisvaporizedbythelaserirradiationofnumericalcontrol,sothatthecolorwillnotfadeonvariousdenimfabrics.Theeffectofimagepatterns,gradualflowershape,catwhiskermatte,etc.addsnewbeautytothedenimfashion.

Denimspraylaserprocessingisanemergingprocessingprojectwithsubstantialprocessingprofitsandmarketspace.Itisverysuitablefordenimgarmentfactories,washingplants,processingenterprisesandindividualstoaddvaluetodenimproductsDeepProcessing.

Leatherfabricmarkings

Lasertechnologyisalsowidelyusedinshoemakingandleatherindustries.Theadvantageoflaseristhatitcanquicklyengraveandhollowoutvariouspatternsonvariousleatherfabrics,anditisflexibleinoperation,anditwillnotcauseanydeformationontheleathersurfacetoreflectthecolorandtextureoftheleatheritself.Italsohasmanyadvantagessuchashighengravingaccuracy,hollowedoutandnoburrs,andarbitraryshapeselection.Itissuitablefortheneedsofprocessingmanufacturerssuchasshoeuppers,shoematerials,leathergoods,handbags,bags,andleatherclothing.

Laserengravingreferstotheoperationmethodofconnectinglaserequipmenttolaserengravingsoftwareandinputtingtheartworkintoautomaticengraving.Laserengravingisthemostmatureandwidelyusedtechnologyinthefieldoflaserprocessing.Usingthistechnique,anycomplexgraphicscanbeengraved.Itcancarryouthollowcarvingandnon-penetratingblindgroovecarving,soastocarveoutvariousmagicalpatternswithdifferentshades,differenttextures,layeringandtransitionalcoloreffects.Withtheseadvantages,laserengravingcaterstothenewtrendofinternationalclothingprocessing.

Appliquecutting

Inthecomputerembroideryprocess,twostepsareveryimportant,namelycuttingbeforeappliqueembroideryandcuttingafterembroidering.Cutting.Inthetraditionalprocessingtechnology,thedefectofthecuttingdieprocessingmethodusedforcuttingbeforeembroideringisthatitiseasytoproducefabricfringing,andtheprocessingaccuracyislimitedbythedie,itisdifficulttoprocesstheheterogeneousgraphics,theproductioncycleofthedieisoften,andthecostishigh.Restrictedthedevelopmentofappliquéembroidery.However,thecuttingafterembroideringmostlyadoptsthehot-cuttingprocessingmethod,whichhasthedisadvantagesoflargecuttingedgegaps,yellowingandhardedges,anddifficultyinalignment.Heterosexualgraphicsrelyonmanualhand-cutting,whichiseasiertoscatterandproducewasteproducts.Therefore,thereisanurgentneedforanadvancedprocessingmethodtoreplacethesetwooldprocessingmethods.

Althoughlaserprocessingisalsoathermalprocessingmethod,itisverysuitableforcuttingtextilefiberfabricsduetothehighfocusofthelaser,theslenderspot,andthesmallthermaldiffusionzone.Thespecificperformanceisinthewiderangeofprocessedfabrics,smoothcuttingwithoutflash,automaticclosing,nodeformation,graphicscanbedesignedandoutputbycomputeratwill,noknifedieandsoon.Thismakeslaserprocessingarecognizedalternativeintheindustry.

Lasermarkingfortrademarks

Lasermarkinghashighmarkingaccuracy,fastspeedandclearmarking.Itcanbeusedinhard,softandbrittleproducts.Featuresofprintingvariouscharacters,symbolsandpatternsonplanes,arcsandflyingobjects.Lasermarkingiscompatiblewiththevariousadvantagesoflasercuttingandengraving.Itcanbepreciselyprocessedonmetalandorganicpolymersheets,andprocessedsmallandcomplexpatterns.Theprintedmarkhastheanti-counterfeitingperformancethatneverwearsout.Itcanbespeciallymadeforclothlabel,leatherlabel,metallabel,andvariouscompanyemblemsandLOGOwithcomplexanddetailedprintingpatterns.Itisthebestchoiceforbrandclothingandapparelprocessing.

Foralongtime,therehasbeenanalignmentprobleminthetrimmingoftrademarks,thetrimmingofembroiderypatterns,andtheperforatedpatchworkinembroiderypatterns.Accurateandefficientcuttingisthecommonexpectationoftheindustry.Theexistingautomaticvisiontrackingcuttingsystemhastakenabigstepforwardonthebasisoftraditionalmanualalignmentcutting,andcanautomaticallylocateandcutthealignmentpointsindifferentbureaus.However,therandomdeformationoftextileproductscannotbeautomaticallycorrected,soalargeamountofwasteproductswillbegenerated.Somecompaniesintheindustryhavesuccessfullydevelopedanautomaticrecognitionedge-findingandcuttingsystem,whichcanautomaticallygenerateacuttingpathbasedontheedgesofthewoventrademarkgraphics,andaccuratelyuselaseredgecutting.Itcanalsoautomaticallypositionandcutandperforatethepatternsintheembroiderygraphics,therebyfundamentallysolvingtheproblemofalignment.

Historicaldevelopment

Althoughlaserdisplaytechnologywasproposedasearlyasthe1960s,itwasnotuntilthebeginningofthe21stcenturythattheprinciplewasfirstrealizedinmycountry.Laserdisplaytechnologysolvestheproblemofhigh-fidelityimagereproduction.

Laserhasthecharacteristicsofgoodmonochromaticity,strongdirectionalityandhighbrightness.Thousandsoflaserworkingmaterialshavebeendiscovered,withwavelengthsrangingfromsoftX-raystofarinfrared.Thecoreoflasertechnologyislasers.Therearemanytypesoflasers,whichcanbeclassifiedaccordingtodifferentmethodssuchasworkingsubstance,excitationmode,operationmode,andworkingwavelength.Accordingtodifferentapplicationrequirements,somespecialtechnologiesareadoptedtoimprovethebeamqualityandindividualtechnicalindicatorsoftheoutputlaser.Themorewidelyusedunittechnologiesincluderesonantcavitydesignandmodeselection,frequencydoubling,tuning,Qswitching,modelocking,frequencystabilizationandAmplificationtechnology,etc.

Inordertomeettheneedsofmilitaryapplications,thefollowingfivelasertechnologieshavebeenmainlydeveloped:①Laserrangingtechnology.Itisthefirstlasertechnologytobepracticallyappliedinthemilitary.Attheendofthe1960s,laserrangefindersbegantobeequippedwithtroops,andmanytypeshavebeendevelopedandproduced.Mostofthemuseyttriumaluminumgarnetlaserswitharangeaccuracyofabout±5meters.Becauseitcanquicklyandaccuratelymeasurethetargetdistance,itiswidelyusedinreconnaissancemeasurementandweaponfirecontrolsystems.②Laserguidancetechnology.Laser-guidedweaponshavehighprecision,relativelysimplestructure,andarenotsusceptibletoelectromagneticinterference.Theyoccupyanimportantpositioninprecision-guidedweapons.Intheearly1970s,thelaser-guidedaerialbombdevelopedbytheUnitedStateswasusedforthefirsttimeonthebattlefieldinVietnam.Sincethe1980s,theproductionandequipmentoflaser-guidedmissilesandlaser-guidedartilleryshellshavealsoincreaseddaybyday.③Lasercommunicationtechnology.Thelasercommunicationcapacityislarge,theconfidentialityisgood,andtheanti-electromagneticinterferenceabilityisstrong.Opticalfibercommunicationhasbecomethefocusofthedevelopmentofcommunicationsystems.Airborneandspacebornelasercommunicationsystemsandsubmarinelasercommunicationsystemsarealsobeingresearchedanddeveloped.④Stronglasertechnology.Tacticallaserweaponsmadeofhigh-powerlaserscanblindhumaneyesandmakephotodetectorsineffective.Theuseofhigh-energylaserbeamsmaydestroymilitarytargetssuchasaircraft,missiles,andsatellites.Tacticallaserweaponsusedforblindness,airdefense,etc.areapproachingthepracticalstage.Strategiclaserweaponsforanti-satelliteandanti-intercontinentalballisticmissilesarestillintheexploratorystage.⑤Lasersimulationtrainingtechnology.Uselasersimulationequipmentformilitarytrainingandcombatexercises,withoutconsumingammunition,trainingsafety,andrealisticeffects.Avarietyoflasersimulationtrainingsystemshavebeendevelopedandproduced,whicharewidelyusedinshootingtrainingandcombatexercisesofvariousweapons.Inaddition,importantprogresshasbeenmadeintheresearchoflasernuclearfusion,theseparationoflaserisotopeshasenteredthestageoftrialproduction,andlaserfuzesandlasergyroscopeshavebeenputintopracticaluse.

Characteristics

Laseriswidelyusedbecauseofitscharacteristics.Thelaserisalmostamonochromaticlightwavewithaverynarrowfrequencyrangeandhighenergyconcentrationinanarrowdirection.Therefore,thefocusedlaserbeamcanbeusedtoperforatevariousmaterials.Taketherubylaserasanexample.Thetotalenergyofitsoutputpulseisnotenoughtocookanegg,butitcandrillasmallholeina3mmsteelplate.Thelaserhastheabovecharacteristics,notbecauseithasdifferentlightenergyfromotherlights,butitspowerdensityisveryhigh,whichisthereasonwhylasersarewidelyused.

Thelaserhasanarrowspectrum,gooddirectivity,andhighpower.Itcanbeaccuratelycontrolledinthebestvisualperceptionareaofthehumaneye,anditiseasytoachieve8Khighresolutionandhighcontrast.Thesecharacteristicsarenotavailableinallotherdisplaylightsourcesatthesametime;Anotheradvantageoflaserdisplayishighviewingcomfortandeyeprotection,becauseitisdiffusereflectionimaging,full-pixelluminescence,andnoshort-wavebluelight.AccordingtothereportoftheChinaElectronicsStandardizationInstitute,laserdisplaytechnologyhasgoodcomfort,lowvisualfatigue,andnoshort-wavebluelightdamage.

Laserhasthefollowingthreecharacteristics:

·Monochromaticwavelength

·Coherence

·Parallelbeam

Latest: Silicon rectifier

Next: working frequency