Chemical etching

Introduction

Chemicaletching

Etchingisatechniquethatremovesmaterialsbychemicalreactionorphysicalimpact.

Etchingtechniquescanbedividedintotwotypes:"wetetching"and"dryetching".

Usuallyreferredtoasetchingisalsoknownasphotochemicaletching,whichreferstotheremovaloftheprotectivefilmoftheareatobeetchedafterexposure,platemakinganddevelopment,andcontactwithchemicalsolutionsduringetchingtoachievetheeffectofdissolvingandcorroding.Theeffectofconcave-convexorhollowmolding.

Itwasfirstusedtomanufacturecopperplate,zincplateandotherprintingconcave-convexplates.Itisalsowidelyusedintheprocessingofweightreductioninstrumentpanel,famousbrandandthinworkpiecesthataredifficulttoprocessbytraditionalprocessingmethods.Aftercontinuousimprovementanddevelopmentofprocessequipment,itcanalsobeusedintheprocessingofprecisionetchingproductsofelectronicthinpartsintheaviation,machinery,andchemicalindustries.Especiallyinthesemiconductormanufacturingprocess,etchingisanindispensabletechnology.

Forexample,thekeyboardofMotoV3,thetextandsymbolsareallformedbyhollowetchingprocess.

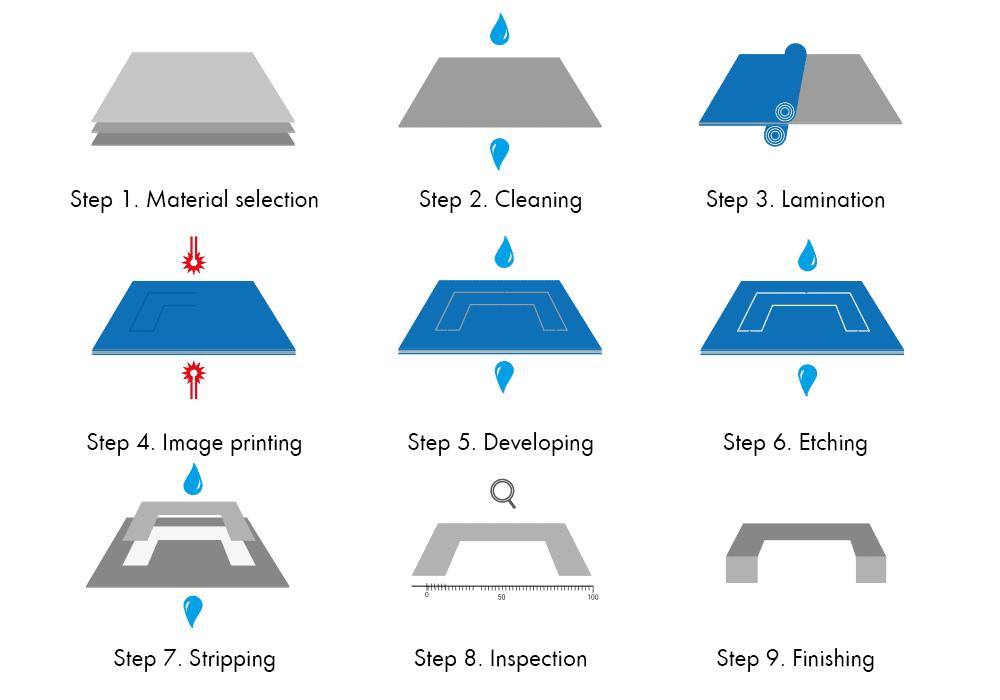

Process

Process:cleaningplate(stainlesssteelandothermetalmaterials)---drying---coating---exposing---developing---etching---release

Chemicalprocessingofglasssurface

Usehydrofluoricacidtocorrodethepartialsurfaceofglassproducts,anddepictvariouspatterns,patternsandscalesonthesurface,Grid,etc.Thechemicaletchingprocessistocoatthesurfaceoftheglassthatneedstobeetchedwithprotectivepaintorparaffinwax.ThenputinanetchingsolutioncomposedofhydrofluoricacidandasmallamountofNH4F,theglasssurfacelayerreactswithhydrofluoricacid,andthegeneratedfluorideisdissolvedintheetchingsolutionordepositedontheglasssurface.

Latest: number

Next: Packet switched network