4D printing

Definition

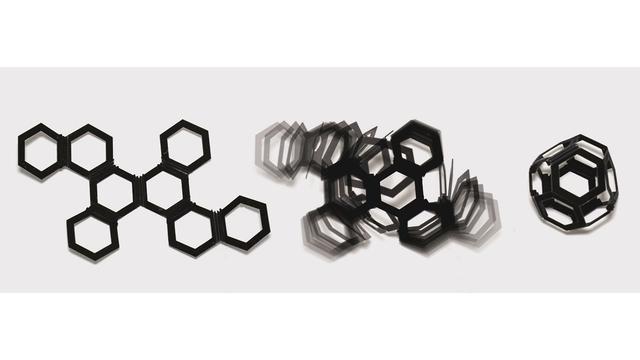

4Dprintingreferstotheuseof"programmablematerials"and3DprintingtechnologytoproduceLight,etc.)three-dimensionalobjectsthatcantransformtheirphysicalproperties(includingshape,density,color,elasticity,conductivity,opticalproperties,electromagneticproperties,etc.).Amongthem,"programmablesubstance"referstoasubstancethatcanprogrammaticallychangeitsshape,density,conductivity,color,opticalproperties,andelectromagneticproperties.Thefourthdimensionof4Dprintingreferstotheshapeorperformanceofanobjectthatcantransformitselfafteritismanufactured.

Thereareatleasttwoformsofobjectsmanufacturedby4Dprinting:oneisthatthepartsoftheobjectareconnectedtogetherandcanbetransformedintoanotherformorperformance;theotheristhattheobjectismadeofseparableThree-dimensionalpixels(avolume-basedpixel,similartoplanarpixels,three-dimensionalpixelsarethebasicunitof"programmablematter",different"programmablematter"hasdifferentthree-dimensionalpixels),three-dimensionalpixelscanbegatheredtoformalargerProgrammablecomponent,whichcanalsobebrokendowninto3Dpixels.

Components

Themaincomponentsof4Dprintingcanbedividedintofourparts:smartorstimulusfeedbackmaterials,4Dprintingequipment,externalstimulusfactors,andintelligentdesignprocess.

1.Smartorstimulusfeedbackmaterials

4Dprintingproductscanshowspontaneouschangesaccordingtothespecificneedsofapplicationscenariosandthespecificactionconditionsofstimulusfactors.Theemergenceof"smart"characteristicsallowsresearcherstocallthebasicmaterialsthatconstitutethistypeofspecialsubstance"SmartMaterial".Thisnamingmethodisbasedonthespontaneousreleaseoftheproductinitsactualapplicationasareference."Simulationfeedback"isoneofthebasicattributesthatconstitutethe4Dprintedbodymaterial.Thisnamingmethodfocusesonthematerial'sabilitytoacceptpresetstimuliandproducecertainfeedbackresults.Theformernamesmaterialsfromtheperspectiveof4Dprintingproductperformance,whilethelatterfocusesonthepropertiesofthematerialsthemselves.

2,4Dprintingequipment

Undernormalcircumstances,a4Dprintingstructureisastructureinwhichdifferentmaterialsarereasonablydistributedthroughprintingequipmentandformedatonetime.Differentmaterialproperties,suchasswellingratioandthermalexpansioncoefficient,canmakeitpossibletochangethestructureinaspecificway.Inrecentyears,thepolymerjet(PolyJetTechnology)3DprintingtechnologydevelopedbyStratasyshasmadegreatprogressinprocessingcompositematerialprinting;selectivelasermeltingtechnology(SelectiveLaserMelting)hasachievedtheuseofhighenergydensityThelasermeltsthemetalpowderlayertocreateauniform3Dmetalstructurewithoutanyadhesivesandadditionalsupport.Theseadvanceshavepromotedthedevelopmentof4Dprinting.

3.Stimulusfactor

Thestimulusfactoristhetriggerusedtochangetheshape,propertiesandfunctionofthe4Dprintingstructure.Thestimulusfactorsthatresearchershaveusedinthefieldof4Dprintinginclude:water,temperature,ultravioletlight,acombinationoflightandheat,andacombinationofwaterandheat.Thechoiceofstimulusfactorsdependsonthespecificapplicationfield,whichalsodeterminesthechoiceofsmartmaterialsinthe4Dprintingstructure.

4.Intelligentdesignprocess

Althoughsmartmaterialsthemselvesplayavitalroleinthechangesintheshapeofprintedobjects,theyarebasedontheinteractionThecomplexdesignprocesswithfullconsiderationofmechanism,predictablebehavioranddemandparameterscanalsoensureoneofthelinkstoachievecontrollableresults.Theadvantageof4Dprintingtechnologyliesinitsabilitytodistributedifferentmaterialsreasonablyinspacetocreatecomplex3Dshapes.Bydesigningthedirectionandpositionofthedistributionofsmartmaterials,wecanmakethestructurechangeinshapeafterbeingstimulatedbythestimulusfactor.

Printingprocess

Becausethe4Dprintingstructurehasthecharacteristicsoftime-basedchanges,thereareoneormoreintermediateformsinthedesignandproductionprocess.

1.Digitaldesignprocess

Traditional3Dprintingtechnologycanobtain3DdataofobjectsthroughprofessionalscannersorDIYscanningequipment,oruse3Dproductionsoftwaretobuild3Ddigitalmodelsfromscratch.Differentfromthemanufacturingprocessof3Dprinting,whichismodeledfirstandthenproduced,4Dprinting,duetoitsvariablecharacteristics,atthebeginningofdigitalmodeling,thematerial'striggermedium,timeandotherdeformationfactors,aswellasotherrelateddigitalparameters,arepre-embeddedIntheprintedmaterials.

2.Middlewareformingprocess

Themiddlewareformingprocessistheprocessfromthebeginningofthe3Dprintingequipmenttothestructureleavingtheworkbench.Thisprocessrequirestheworkofabrandnew3Dprintingfacility.Gladmanetal.believethatthe4Dprintingprocessneedsthesupportofappropriatemathematicalmodels.Themathematicalproblemsinthisprocessinclude:howtopredictthetime-basedmorphologicalchangeprocessofthestructure,includingthechangedmorphology;howtoprovideatheoreticalmodeltoavoidcomponentcollisionsduringtheself-assemblybehavior;howtoreducethetestintheself-assemblyprocessWrongsex.Thesemathematicalproblemsthatneedtobeconsideredmustbejudgedandresolvedthroughintelligentcomputingchips.Itisworthnotingthatinthefuture,artificialintelligencechipscanbeimplantedin3Dprintingequipment,thatis,3Dprintingequipmentwillalsobe"intelligent."Afterthedigitaldesigniscompleted,itistransmittedtotheprintingequipmentfordataanalysis,andthematerialscanbereasonablyarrangedtoensurethefinalprintingeffect.Itcanbepredictedthatthefuture4Dprintingequipmentwilldevelopinthedirectionofstandardizationandmodularization.Thereplaceabilityofdifferentmodulescanbasicallyguaranteethesupportfordifferentmaterialsanddifferentplatforms.

Mainadvantages

1.Thephysicalobjectcanbetransformedfromoneformtoanother,providingmaximumproductdesignfreedom.

2.Drivers,logicandperceptioncapabilitiescanbeembeddedintheprintingcomponentswithoutadditionaltimeandcost.

3,canbecustomizedproductioninthesamebatchofproducts.

4.Theproductionofpersonalizedproductsisauniqueadvantageof4Dprinting.

5.Theextremelysimplestructurecanbeprintedfirst,andthentransformedintoastructureandsystemwithcomplexfunctionsthroughexternalstimulation.

6.Once4Dprintingmaterialsaremanufacturedandembeddedwithdynamicfunctions,thefunctionsofthefinishedproductwillexceedexpectations.

7.Thesupplychainandassemblylinecanbeeliminatedfundamentally.

8.Usedesignandprogrammingtorealizethedigitizationofthematerialworld.

9.Digitalfilescanbesenttoanyplaceintheworld,andappropriate3Dpixelscanbecollectedtomanufacturetherequiredproducts.

10.Thedesignandmanufacturingof3Dpixelswillbecomeanemergingindustry,andtheimpactwillbeextremelyfar-reaching.+

11.Scientistsandengineerswillbeinspiredtoimagineavarietyofmulti-functionaldynamicobjects,andthenmaterialprogrammingwillbecarriedoutandrealizedby4Dprinting.Thenewfieldof"materialprogramming"mayemerge.

Applicationfields

(1)Biologicalandmedicalfields

1.Humantissuesandtissuesandorgans

Thematerialfor4Dprintingbloodvesselsdoesnotnecessarilyrequirethecellsandtissuesofthepatienthimself.Itisonlynecessarytoprogramtheparameterssuchaspracticeandtriggermediainthematerialthroughsoftwaredesigntosolvetheuniquenessofthematerial.Theself-adjustingcharacteristicsof4Dprintingproductsmakeitpossibletoproduceanduseinstantaneously.Intermsofapplicationadaptability,4Dprintedbloodvesselshavetheeffectofself-regulationandself-repair,whichmakesitsapplicationinthebiologicalandmedicalfieldshaveeffectsthatothertechnologiescannotmatch.

2.Medicalequipment

Themainapplicationconceptof4Dprintingistofocusonmedicalequipmentforhumanimplants,suchasnanorobots,organstents,etc.

(2)Militaryindustryfield

The4Dprintedstructurehasself-assembly,multi-functionandself-repaircapabilities,whichcanmakefuturemilitaryequipmentaccordingtodeploymentDifferenton-siteenvironmentsandcombatobjectives,flexibleadjustmentscanbemadetoadapttoreal-timecombatconditionsandimprovecombateffectiveness.Thecamouflageclothingcombinedwith4Dprintingtechnologycanbereshapedintotherequiredformaccordingtotheseasonandsurroundingenvironmentwhiletakingintoaccounttheportability,providingconveniencefortheinvestigatorstoperformtheirtasks.4Dprintingcanalsopresentlarge-scalemilitaryequipmentinamuchsmallershapethantheactualshapebeforeitisarranged,andthenplacethe4Dprintedstructureinaspecificposition,andthenautomaticallydeformandassembleit.AfteruseItcanberecycledandtakenaway.

(3)Productdesignfield

Differentfrom3Dprinting,4Dprintingwillnolongerneedtobeimplementedthroughasetof"customization"proceduresPersonalizedproductproduction,butcanexpressone'sownideasandmaketheminstantly,andcanupdateone'sowncreativityatanytime,soastobuildone'sownpersonalizedlifewithpersonalizedelements,sothatprivatecustomizationcanbeturnedtoprivatefactories,andproductinnovationcanbeacceleratedspeed.UnderthebackgroundoftheInternet+era,digitalfilescanbecopiedindefinitelywithoutaffectingthequality,and4Dprintingcanextendthisdigitalprecisiontothephysicalfield,therebyensuringtheaccuratemassproductionofphysicalproducts,reducingthedefectrateandincreasingProductivity.

(4)Vehicles

Inthefuture,peoplecanevenbuycarcomponentsaccordingtotherequiredcarperformance,externalshape,internalstructure,etc.,andpassthecomponentsanytime,anywhereTheself-assemblyformofpersonalizedcustomizedautomotiveproducts.Atthesametime,thecurrentsocial"difficultparking"problemisgraduallyenlargedwiththeincreasingconsumptionofresourcesandspace,andcarscanevenbefoldedintoashapethatdoesnottakeupspaceinthefuture,makingtheparkingproblemnolongeraheadache.Inthefuture,4Dprintedcarswilluseinnovativesmartmaterials.Whentheexternaltriggeringmediumcausedbymajoraccidentsornaturaldisastersactsonthematerials,thefeedbackmethoddesignedcanensurethesafetyofpassengersinthecartothegreatestextent.Inthefuture,airbagsmaybemorecreative.Replacedbystrongprotectivemeasures.

(5)Constructionandaerospacefields

4Dprintinghasunlimitedpossibilitiesintheconstructionfield.Taketheundergrounddrainagesystemasanexample,using4DprintingThe“adaptive”waterpipedevelopedbytechnologycanchangeitspipediameterandmaterialrigidityaccordingtothedifferentforcesontheouterwallofthewaterpipe.Forexample,whenencounteringnaturaldisasterssuchasfloodsandearthquakes,itcanexpandthediameterormakethematerialflexibletoensureThewatersupplyisnormal.Inaddition,thephysicalspaceofthehouseconstructedby4Dprintingwillbegivenvariability.Accordingtotheeffectofstimulatingfactorssuchaslightchanges,theinternalstructureofthehousecanbechangedaccordingtouserneeds.Forexample,whenmeetingguests,thebedroombecomesanemptyspace.The4Dprintedhousematerialscanallocateidlebedroomspacetothepublicspaceneededbythegueststhroughaseriesofchanges.

Similartotheconstructionindustry,theaerospaceindustryalsohasextremelyhighrequirementsforthereasonableallocationofspace.Hugeequipmentneedstobetransportedbyspaceshuttlestoenterspace.Theself-assemblybehaviorof4Dprintedobjectscansavealotofspaceinthetransportationprocess.Theprintedcomponentscanbesenttospaceinashapethatisconvenientfortransportation,andtheautomaticshapetransformationandassemblybehaviorsinspacecanbecompleted,whichwillgreatlyreduceTransportationcostanddifficulty.Fortheaviationindustry,aircraftmanufacturedusing4Dprintingtechnologycanself-decomposewhenfacedwithspecificenvironmentalchanges,andprovidepassengerswithtimelyandeffectiveprotectioninthemostidealstate(suchasacapsulesafetyshield).

(6)Educationfield

4Dprintinghasalsoopenedanewwindowfortheeducationindustry,butfewinstitutionsandscholarshavestudiedandexploredhowto4Dprintingtechnologyisusedintheeducationfield.Traditionalteachingaidsandmodelsdonothavethe"four-dimensional"dynamics.Ifteachersusespecificstimulusmethodstocombinethemodelswiththeclassroomcontentinapredeterminedchangemode,theycanarouselearningenthusiasmandincreaseconcentration.

Latest: Compound effect

Next: Microform